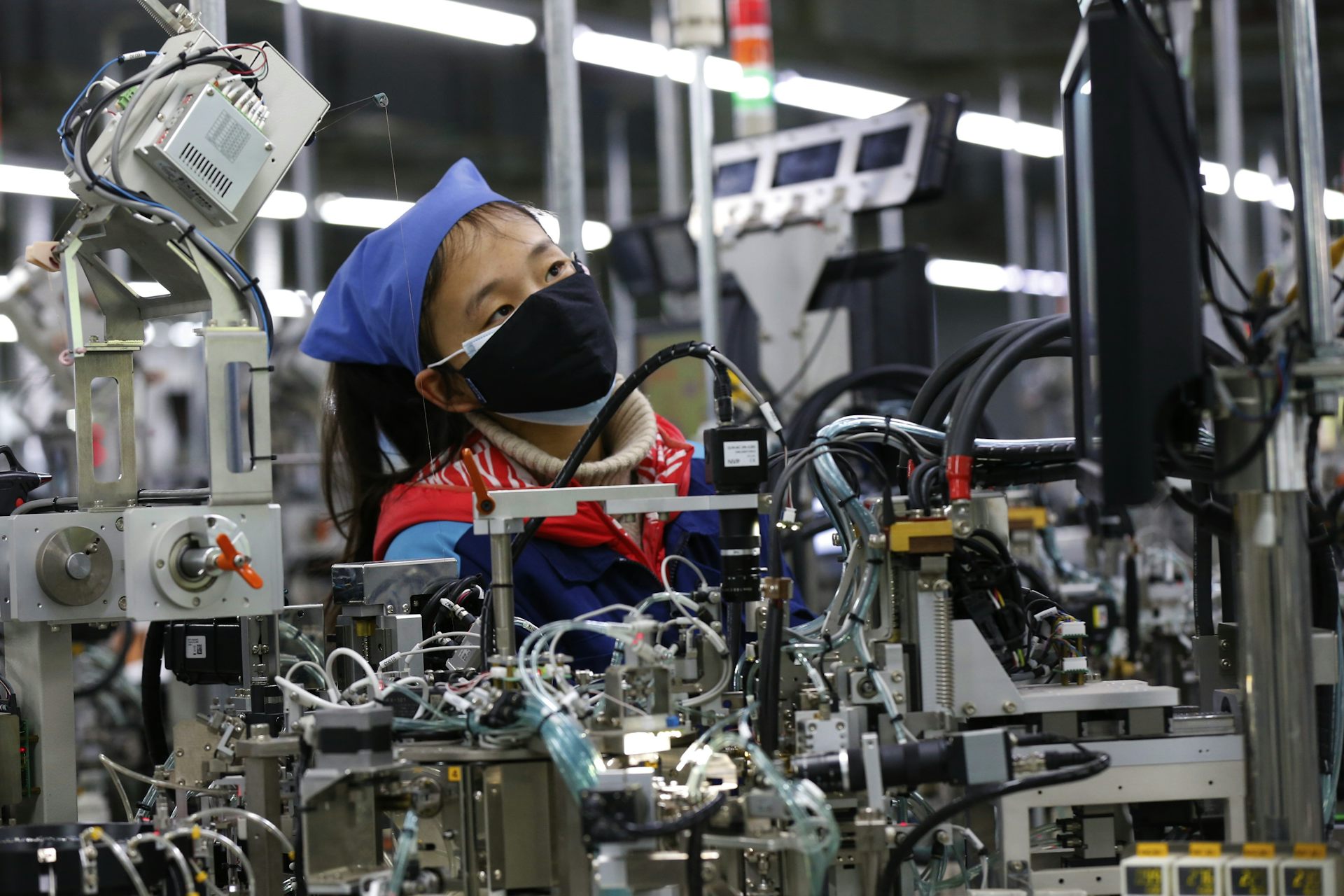

High-tech shortages loom as coronavirus shutdowns hit manufacturers

Feb 13, 2020

There are now more than 45,000 confirmed cases of the coronavirus dubbed COVID-19 by the World Health Organization, and the disease has caused at least 1,115 deaths. The impact of the virus is now reaching way beyond public health: China is at the heart of global manufacturing, and as supply chains suffer, panic is beginning to set in.

In many provinces across China the government has urged hundreds of millions of workers to stay home to help reduce the spread of the virus. As a result, many factories have stayed closed since the Lunar New Year holiday in late January, halting the production of products and parts destined for countries around the world, including Australia.

Apple is one of the most high-profile companies affected, with its manufacturing partner Foxconn hitting a lengthy production delay, but they are far from alone.

Global supply chains, global problems

The sectors hit hardest appear to be high-tech electronics, pharmaceuticals and the automotive industry.

Globalised supply chains and just-in-time manufacturing mean many seemingly unrelated products are vulnerable to pauses in the flow of goods from China.

It only takes one small missing part to bring entire supply chains to a standstill. If a tyre manufacturer in the United States doesn’t receive valves from a supplier in China, a car plant in Germany won’t receive any tyres, and therefore can’t ship finished cars to its customers.

Something similar happened to automotive giant Hyundai, which had to suspend all operations at its manufacturing plant in South Korea due to a lack of parts from China.

Even tech companies such as Samsung, Google and Sony, which have moved their factories out of China in recent years, are being affected. They still rely on China for many components such as sensors or smartphone screens.

It is not just large businesses that will feel these effects. Many small businesses around the world also source products and parts from China.

The supply of these is now uncertain, with no sign yet as to when normal service may resume. For products and parts that are still being manufactured in China, new enhanced screening measures at all Chinese border crossings are likely to cause further delays.

How will Australia be affected?

The effects of the coronavirus are also being felt in Australia. China is our largest trading partner for both imports and exports. According to the United Nations Comtrade database, Australian imports from China were valued at A$85.9 billion in 2018. The biggest product categories were electronics and electrical equipment, making up A$19.8 billion, and machinery, which accounts for another A$15.7 billion.

Moreover, 90% of all Australia’s merchandise imports are from China, and half of those are engineering products such as office and telecommunications equipment.

Besides the well-publicised impact on airlines, universities and tourism, Australian construction companies are warning clients of upcoming project delays as a result of forecast disruptions in materials sourced from China. Aurizon, Australia’s largest rail operator, has said the coronavirus will delay the arrival of 66 new rail wagons being made in Wuhan, the city at the epicentre of the outbreak.

Expect shortages of high-tech goods

Product shortages could also soon be visible on retailers’ shelves, with electronics stores such as JB Hi-Fi and Harvey Norman expected to experience significant disruption to their supply of computers, televisions and smartphones.

When shortages like this occur, customers will struggle to buy the products they want, when they want them. The only channels available might be third-party resellers offering highly inflated prices. In extreme cases, supply shortages like these can also lead to panic buying and stockpiling.

More uncertainty ahead

It is commonly said that “when China sneezes, the world catches a cold”. So what is the long-term diagnosis for the coronavirus breakout, and what will the economic symptoms be?

As so much is still unknown about COVID-19, with no vaccine or formal means of preventing it spreading having emerged yet, it’s too early to predict what the full impact will be.

For many industries the next few months will bring high levels of uncertainty, with disruptions certain to continue, before recovery programs can start to gain traction.

This is obviously a worry for many organisations, but could also be a period of new opportunity for others, as the world comes to terms with this latest global health crisis. Supply chains that are agile enough to react quicker than their competitors’, or those with more robust risk management plans, might find themselves gaining greater market share as a result of this crisis.

Source: The Conversation AU