Press Releases

PET recycling has been a hot issue around the world recently. PET is one of the most used plastic materials in the world today, with an annual production of 70 million tons. The data shows that the world produces 359 million tons of plastic each year, and the recycling efficiency of plastic waste is about 30%. According to the current industrial development system, by 2030, global plastic production may increase by 40%. With the diversification of uses and the failure to implement recycling, plastic ocean pollution is expected to exceed 300 million tons by 2040. It is one of the great disasters to the environment.

While ensuring the properties of plastic, how to quickly degrade it has also become a problem that scientists want to solve. After searching various news and papers can see that we have made various attempts to degrade plastics.

ACERETECH is a manufacturing enterprise specializes in plastic waste recycling and pelletizing machine. The members of our professional R&D team with cutting-edge technology come from Europe, Mainland China, and Taiwan. ACERETECH aims to bring the world's leading and mainstream recycling technology to all of the world's customers.

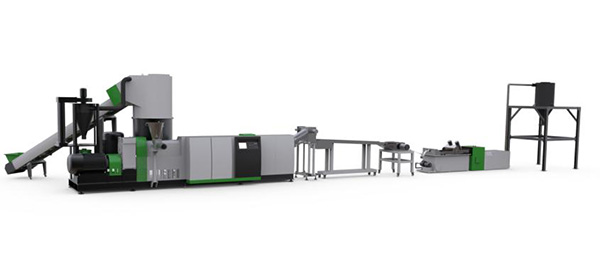

ACERETECH ACS series pelletizing machine is our main line of production. The automatic strand pelletizing machine can easily deal with the waste plastic PET flakes after being washed. The decreased value of IV (Intrinsic Viscosity) can be controlled within 0.05. For in-house recycling, the data can be controlled within 0.03.

Size reduction, pre-heating and pelletizing, 3 in 1 integrated system, less cost. More effective and stable system for plastics of low bulk density. Higher output and lower energy consumption. Lower investment for a higher performance machine. Standard production and management in the workshop. Combines size reduction, plasticization, and pelletizing in an integrated system. Qualified for soft plastics as well as rigid flakes with an innovative specific design.

Aceretech is good at developing and producing high-efficiency waste plastic recycling equipment. Compared with traditional recycling machines, Aceretech integrated recycling pelletizing systems can more effectively solve the shortcomings of overfeeding or underfeeding due to combining cutting compaction, extrusion, and granulation systems into one. The production capacity and quality of the overall recycling process can also be stabilized at the same time.

High efficiency filtration integrated single screw recycling pelletizing system

A dual filtering system is implemented on an extruder, which has perfect filtering effects for recycled materials with relatively high impurity content. For example, the final LDPE pellets; can reach the application of blown film level or higher. On this extruder, the first self-developed self-cleaning filter developed by Aceretech; eliminates the tedious manual screen change and automatically cleaning and slagging; the second super-large area double-column screen changer extends the screen change time and reduce the changing frequency, also can be replaced with different precision filters to achieve different application requirements. These two filters can give full play to the efficiency of the exhaust section, and the plastic pellets will be significantly improved. The operating system can be remotely interconnected to realize the digital intelligent workshop and enter the digital production era.

ACS-H Model 3 in 1 Integrated Plastic Recycling Pelletizing System for film / rigid plastic recycling.

* Turnkey solution from shredding / Crushing, washing, drying solution for post consume plastic recycling, such as milk bottle, mulch film, PET / PA filaments etc;

* Plastic size reduction solution, such as Shredder, Crusher o combined both Shredder and Crusher; different size of machines for different output.

* Other auxilary machines for plastic recycling

Plast Eurasia exhibition was held on 4-7 Dec 2019 in Tuyap, Istanbul, which has attracted over 50,000 visitors and exhibitors from 44 countries to attend the largest fair on plastic and rubber processing industry.

AceREtech team met and talked with a lot of visitors and clients in these days, to introduce our new technology for plastic recycling machines: plastic washing machine, plastic pelletizing recycling machine, PET Bottles Recycling Plant and so on.

With advanced and optimized design, high-level configuration, AceREtech’s machines run stably and effectively compared with most competitors, has won golden reputation in east-European countries.

From size reduction, friction and flotation washing machine, drying machine, to extruder pelletizer, AceREtech has much experience in recycling HDPE, LDPE, LLDPE, PP, ABS, PS, EPS, EPE, EPP, PET, PA6, PA66, and always glad to provide suitable solutions for recyclers all over the world.

ACERETECH Machinery Co., Ltd.

- China

- No. 18, Yuefeng Road, Nanfeng Town, Zhangjiagang City, Jiangsu Province 215628, China

- 86-512-58622012

- 86-512-58622013